Sirio

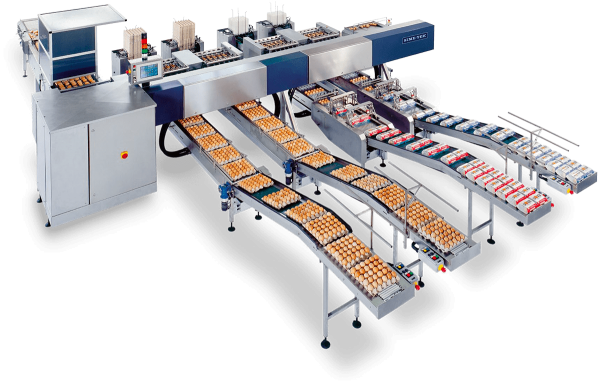

From 36 to 90.000 eggs/h

36 – 90.000 eggs/h 100 – 250 cases/h

8-12-16

4+

3-8 kw +

1,5kw/line

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Accumulator table made of a large stainless steel mesh where it’s possible to unload eggs manually or from any of our automatic loaders, and connect multiple conveyors coming from the farm. Made of a large stainless-steel mesh which allows any liquid or egg shell to fall down directly to the drawers without dirtying the rest of the eggs. Soft rotating star wheels manage the incoming egg flow and divides the eggs based on the number of rows of the machine.

An infeed belt connected directly to the conveyor coming from the shed/s or attached to an automatic or manual loader, brings the eggs to the accumulator, where thanks to special rotating “stars” (made of composite material) the eggs are introduced in the roller conveyor according to the number of weighing lines of the plant (2, 4, 6 or 8 rows). This simple mechanism keeps the eggs in constant movement, ensuring a constant flow to the roller conveyor of the system and thus increasing its efficiency.

Roller conveyor in material suitable for food use, with low-impact rollers that guarantee a continuous rotation of the eggs, to facilitate candling and manage their flow in the machine.

Candling cabin with sun coloured bulbs gives the operator excellent vision to remove faulty eggs quickly. Neon bulbs and a mirror, with the rollers moving forward and backwards to let the eggs roll and help the operator in the candling process.

Sime-Tek’s electronic grading system guarantees maximum precision in the weighing of the eggs. This is due to the fact that the weighing is carried out from stationary scales rather than moving as in most of the systems on the market. The weighing is always carried out by difference between gross and tare weight, so as to guarantee constant accuracy even in the presence of deposits of dust or egg residues, which happens in certain production cycles. Thanks to this system it is possible to predetermine and modify at any time the exit direction of each egg.

The touch-screen panel, manages the entire working cycle of the plant, and provides daily statistics and data reports. The software installed, versatile and interfaceable with any printer, is easy to use and allow real-time control of all system functions. The system, in addition to managing weight settings and providing statistics and information such as egg/packages count, is equipped with online connectivity and a special webcam, for remote assistance in case challenges occur. The operator can be equipped with a software interfaced to the machine which he can use to control and manage the system remotely at any time. 22

An horizontal moving bar that receives the eggs from the weighing section and safely transfers each egg individually to the carriers in the distribution line by precisely matching its speed. Once the eggs are placed in the carriers of the distribution line, the eggs will be transported to the final destination in the packing lines.

Once the eggs arrive at the designated packing lines, they are released into an area called reservoir. The release is slowed down, and the eggs are accompanied in the reservoir passing through soft rotating brushes in continuous motion (Sirio only) In the entrance of the packers, the quick and safe transport of the eggs is guaranteed by the movement of the reservoir (in large steel mesh), which, together with the soft “rotating stars”, keeps the eggs in constant movement and manages the continuous flow to the packer. The reservoir system guarantees maximum production efficiency, and eliminates the need for by-pass lines, since the machine can work continuously even when a packer is stopped to change the packages or make adjustments.

The manual exits consist of special stainless steel tables (or food-grade plastics on smaller models) placed in strategic points of the plant where non-standard eggs are conveyed (particular weights / qualities compared to the production standard).

Sime-Tek denesters are universal and can be quickly adapted to any type of packages (plateaux, plastic packaging or wood pulp). The particular system for the regulation of the denester allows for a quick and easy change between the different size and type of packages. The change in the denester is carried out by stopping only the packing line involved, while the rest of the machine continues working.

The outlets of Sime-Tek packers are specifically designed to allow a delicate but at the same time rapid unloading of the packaged product, ergonomic and easy to access for the final operator. The outputs can be standard or motorized for feeding the palletizers (where present), or end-of-the-line automation processes.

The packers represent the unique and recognizable style of Sime-Tek. The original system of protection and support of the eggs in the packaging is optimized in the movement thanks to the use of pre-stressed steel, which makes the packing more precise and delicate in the treatment of the product and the deposit in the packages. The packing system is also equipped with special “Sime-Tek hands”, which accompany the eggs in the packages and deposit them at the lowest height possible. 26

Sime-Tek’s unique deposit method guarantees that the eggs are gently deposited into the packs, at the lowest height in the industry, guaranteeing a safe and precise packing process.

Automatic closing device which is used to close the cover of the consumer packages. The sensors before the closing system will warn the operator in case of missing eggs in the packages.

The machine can be equipped with a semi-automatic candling system, which includes a special dedicated exit for discharging broken eggs before they enter the grading system, and a special wand with two buttons. The operator has the option of pressing one button, to completely discharge the selected egg, or the other, to send the egg to a dedicated packing line for further inspection, or other use.

For the disinfection and sterilization of eggs and rollers, Sime-Tek systems can be equipped with a special chamber where the eggs pass under ultraviolet lamps specifically made for the removal of the bacterial charges present on the eggs and on the rollers of the machine.

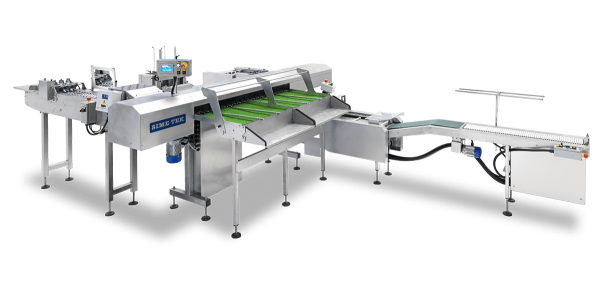

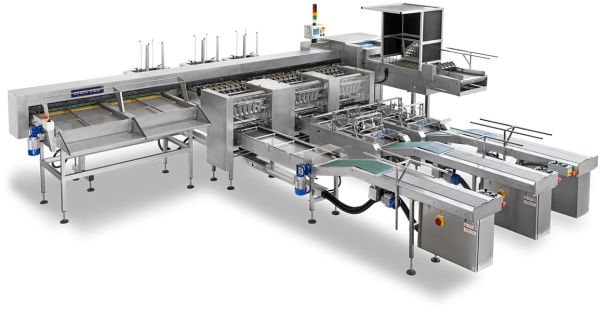

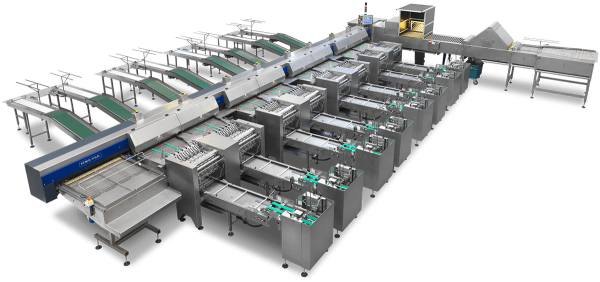

Sirio is the highest capacity model in our range and it encompasses all the technology

and innovation developed throughout the years. With high capacity packing lines and an

“open mind”, it is ready for connecting to any external software or hardware, to allow for

the highest level of automation.

In larger scale production, the efficiency of our machines, combined with our double concept

of work (90.000 eggs per hour is done by joining 2x45.000 eggs per hour machines), guarantess

virtually zero downtime and the maximum efficiency at the lowest operational cost.

Standard components

Accumulator

Infeeder

Roller conveyor

Manual candling

Electronic weighing

Touch screen

Distribution

Packing unit entrance

Manual output

Denester

Packer exit

Packer

Sime-Tek Hands

Closing device

Accumulator table made of a large stainless steel mesh where it’s possible to unload eggs manually or from any of our automatic loaders, and connect multiple conveyors coming from the farm. Made of a large stainless-steel mesh which allows any liquid or egg shell to fall down directly to the drawers without dirtying the rest of the eggs. Soft rotating star wheels manage the incoming egg flow and divides the eggs based on the number of rows of the machine.

An infeed belt connected directly to the conveyor coming from the shed/s or attached to an automatic or manual loader, brings the eggs to the accumulator, where thanks to special rotating “stars” (made of composite material) the eggs are introduced in the roller conveyor according to the number of weighing lines of the plant (2, 4, 6 or 8 rows). This simple mechanism keeps the eggs in constant movement, ensuring a constant flow to the roller conveyor of the system and thus increasing its efficiency.

Roller conveyor in material suitable for food use, with low-impact rollers that guarantee a continuous rotation of the eggs, to facilitate candling and manage their flow in the machine.

Candling cabin with sun coloured bulbs gives the operator excellent vision to remove faulty eggs quickly. Neon bulbs and a mirror, with the rollers moving forward and backwards to let the eggs roll and help the operator in the candling process.

Sime-Tek’s electronic grading system guarantees maximum precision in the weighing of the eggs. This is due to the fact that the weighing is carried out from stationary scales rather than moving as in most of the systems on the market. The weighing is always carried out by difference between gross and tare weight, so as to guarantee constant accuracy even in the presence of deposits of dust or egg residues, which happens in certain production cycles. Thanks to this system it is possible to predetermine and modify at any time the exit direction of each egg.

The touch-screen panel, manages the entire working cycle of the plant, and provides daily statistics and data reports. The software installed, versatile and interfaceable with any printer, is easy to use and allow real-time control of all system functions. The system, in addition to managing weight settings and providing statistics and information such as egg/packages count, is equipped with online connectivity and a special webcam, for remote assistance in case challenges occur. The operator can be equipped with a software interfaced to the machine which he can use to control and manage the system remotely at any time. 22

An horizontal moving bar that receives the eggs from the weighing section and safely transfers each egg individually to the carriers in the distribution line by precisely matching its speed. Once the eggs are placed in the carriers of the distribution line, the eggs will be transported to the final destination in the packing lines.

Once the eggs arrive at the designated packing lines, they are released into an area called reservoir. The release is slowed down, and the eggs are accompanied in the reservoir passing through soft rotating brushes in continuous motion (Sirio only) In the entrance of the packers, the quick and safe transport of the eggs is guaranteed by the movement of the reservoir (in large steel mesh), which, together with the soft “rotating stars”, keeps the eggs in constant movement and manages the continuous flow to the packer. The reservoir system guarantees maximum production efficiency, and eliminates the need for by-pass lines, since the machine can work continuously even when a packer is stopped to change the packages or make adjustments.

The manual exits consist of special stainless steel tables (or food-grade plastics on smaller models) placed in strategic points of the plant where non-standard eggs are conveyed (particular weights / qualities compared to the production standard).

Sime-Tek denesters are universal and can be quickly adapted to any type of packages (plateaux, plastic packaging or wood pulp). The particular system for the regulation of the denester allows for a quick and easy change between the different size and type of packages. The change in the denester is carried out by stopping only the packing line involved, while the rest of the machine continues working.

The outlets of Sime-Tek packers are specifically designed to allow a delicate but at the same time rapid unloading of the packaged product, ergonomic and easy to access for the final operator. The outputs can be standard or motorized for feeding the palletizers (where present), or end-of-the-line automation processes.

The packers represent the unique and recognizable style of Sime-Tek. The original system of protection and support of the eggs in the packaging is optimized in the movement thanks to the use of pre-stressed steel, which makes the packing more precise and delicate in the treatment of the product and the deposit in the packages. The packing system is also equipped with special “Sime-Tek hands”, which accompany the eggs in the packages and deposit them at the lowest height possible. 26

Sime-Tek’s unique deposit method guarantees that the eggs are gently deposited into the packs, at the lowest height in the industry, guaranteeing a safe and precise packing process.

Automatic closing device which is used to close the cover of the consumer packages. The sensors before the closing system will warn the operator in case of missing eggs in the packages.

Optional

Automatic

loader

Semiautomatic

candling

Automatic

candling

Crack Detector

UV disinfection

Category indicator

Motorized output

Print unit

Automatic stracker

Ink-jet shifter

Mini robot

Blood detector

Egg Washer

loader

Capacities from 30.000 to 60.000 eggs/hour, with layouts adaptable to the existing spaces and to the different working flows. With single or double loading head, they can be linked to each other to reach the perfect configuration for the client. Following Sime-Tek’s core values, they guarantee the maximum efficiency, safety and adaptability, while keeping the investment low.

candling

candling

The machine can be equipped with a semi-automatic candling system, which includes a special dedicated exit for discharging broken eggs before they enter the grading system, and a special wand with two buttons. The operator has the option of pressing one button, to completely discharge the selected egg, or the other, to send the egg to a dedicated packing line for further inspection, or other use.

loader

candling

candling

The system automatically recognizes the dirty eggs, and decide whether to discard or direct them to a specific outlet, and the broken eggs, which are immediately removed from the plant to avoid cross contamination on the rest of the system.

candling

Automatic detection system for micro and macro breakage, with the possibility to define in a personalized way the degree of breakage to be discarded. Recognizes the micro breakages of the egg, invisible to the naked eye, and broken eggs without perforation.

candling

For the disinfection and sterilization of eggs and rollers, Sime-Tek systems can be equipped with a special chamber where the eggs pass under ultraviolet lamps specifically made for the removal of the bacterial charges present on the eggs and on the rollers of the machine.

The machine can be equipped with a motorized conveyor belt that allows the stacks of ready trays to move towards the palletizing area and to further speed up the production process.

Simple mechanical stamping system, can print a fixed code on the eggs directly on the farmpacker during collection.

The exit lines, both on graders and packer, can be equipped with automatic stackers that stacks a pile of 6 trays. This optional guarantees an even quicker palletisation process for a more automated collection process. On graders, the stackers can be placed in conjuction with the closing system, allowing the operator to select the preferred working method by simply deactivating one or the other when not in use.

The ink-jet shifters can move a printing head (or cartridge system) to print in multiplepositions on the egg boxes.

Automated solution to receive boxes; from two grader lines and fill pre-made cases. Fully customizable according to different products needs. Tailor-made configurations to fit in existing spaces or create more efficient workflows. Easy and functional operation thanks to the collaborative functioning of the robot.

Automatic blood detection, capable to detect the presence of blood inside any type of commercial eggs, with maximum precision.

loader

Features

Highest capacity at

the lowest operational cost

Modularity in design

and configuration

Full adaptability to

third-party softwares

Remote support always

free-of-charge

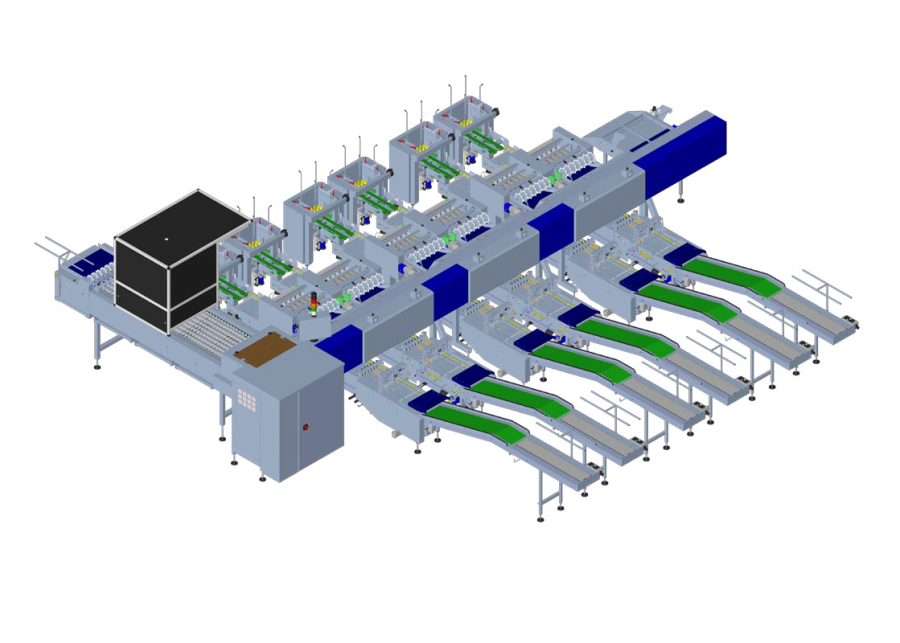

Dimensions and layouts

The layouts shown are for illustrative purposes only and represent only some

of the configurations available. For a customized layout, please contact one of

our representatives.

Certified Second Hand

Every second hand machine gets thoroughly tested and refurbished by Sime-Tek technicians,

and comes with the same warranty as the new. Discover more about the process and

what's available.